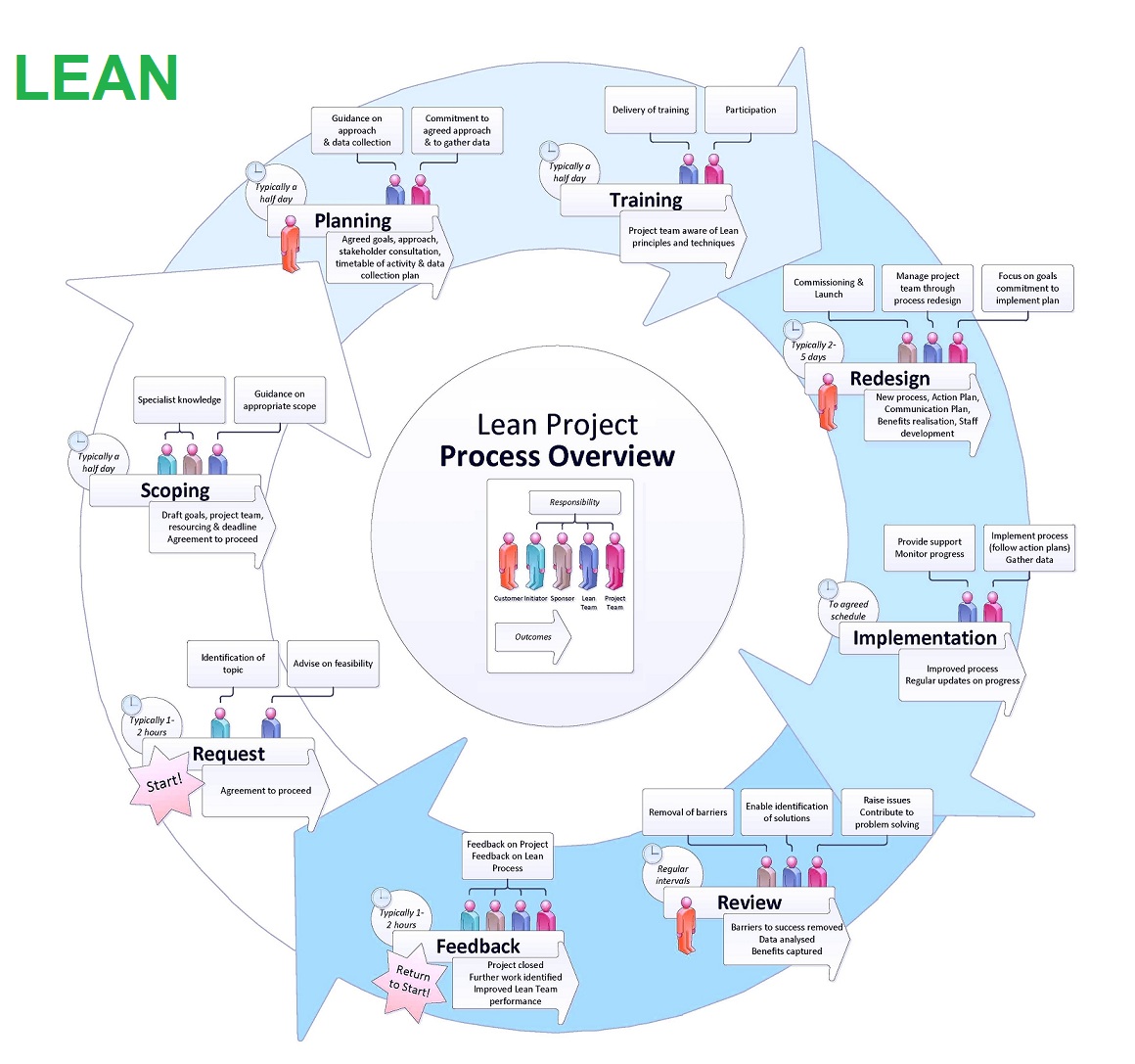

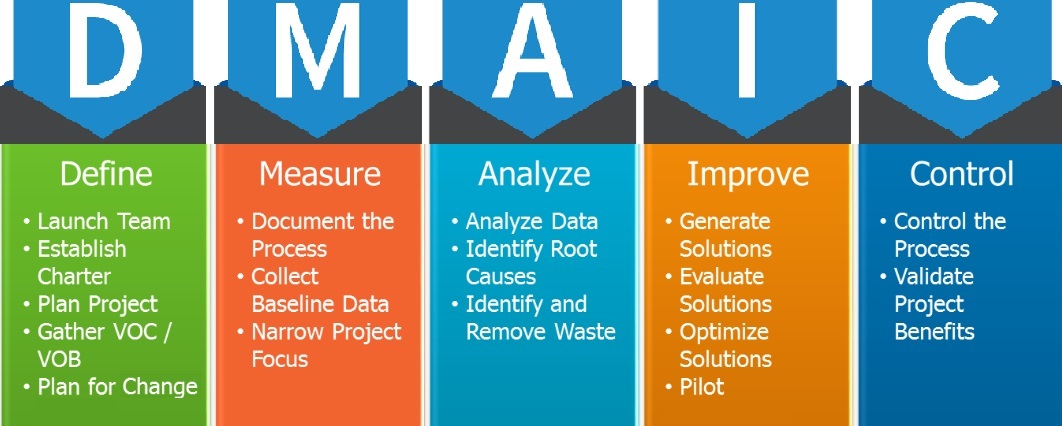

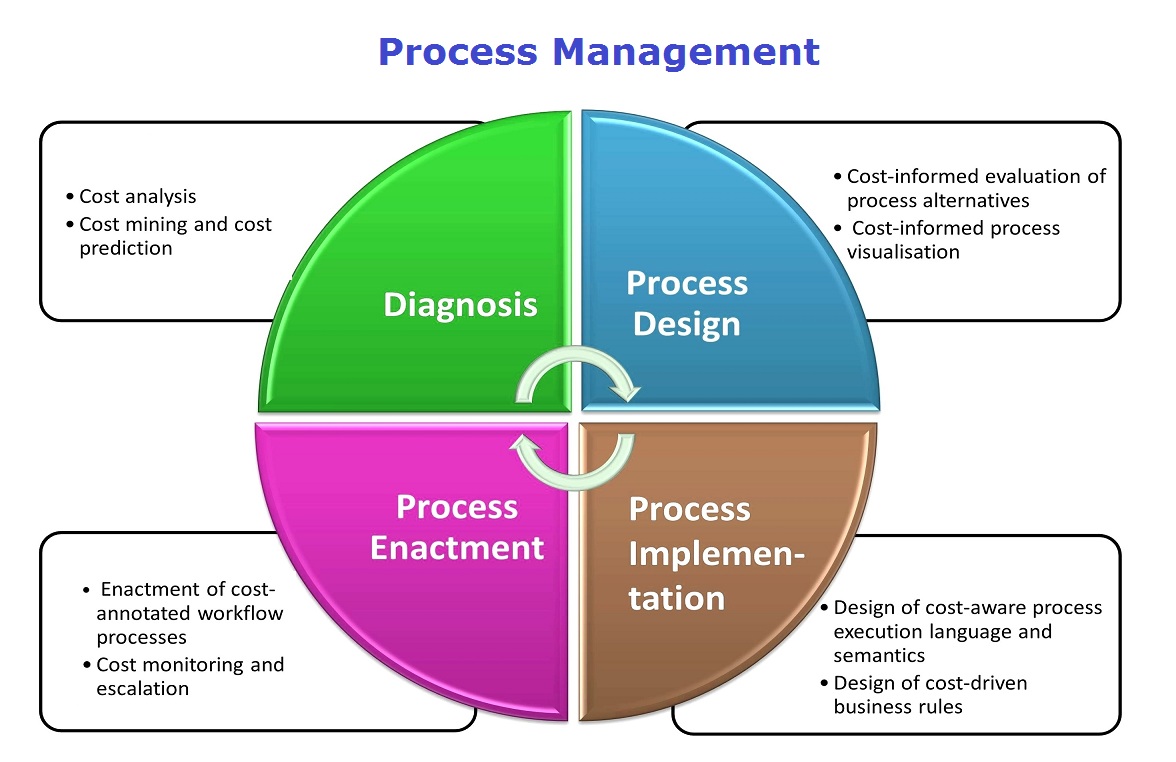

Process improvement is the practice of optimizing processes to improve quality, performance, speed, or anything else that can make a process more efficient and provide a better experience for users and employees. There are different methodologies that businesses can use to improve their processes, including Six Sigma, Lean, and Business Process Management (BPM).

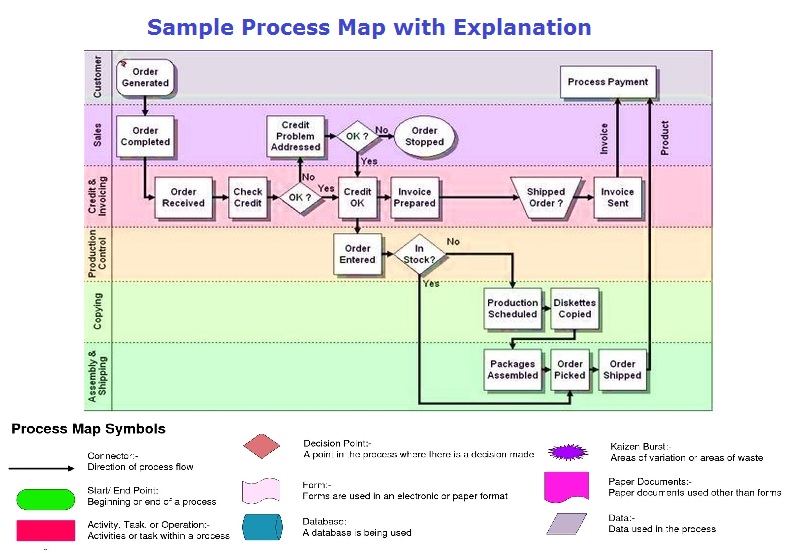

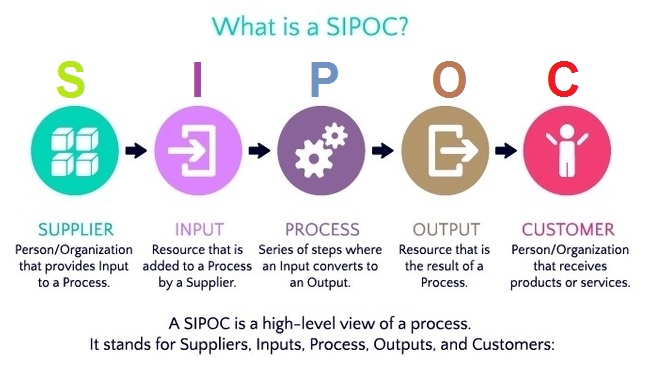

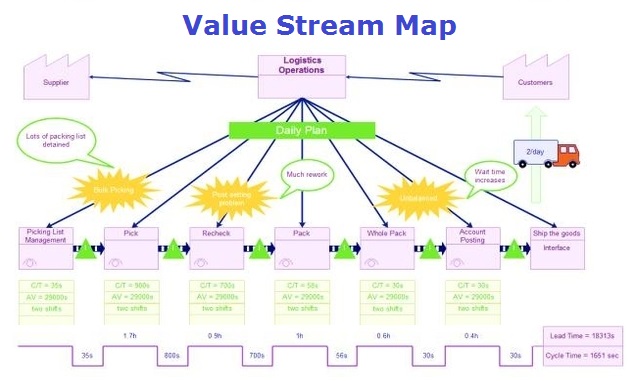

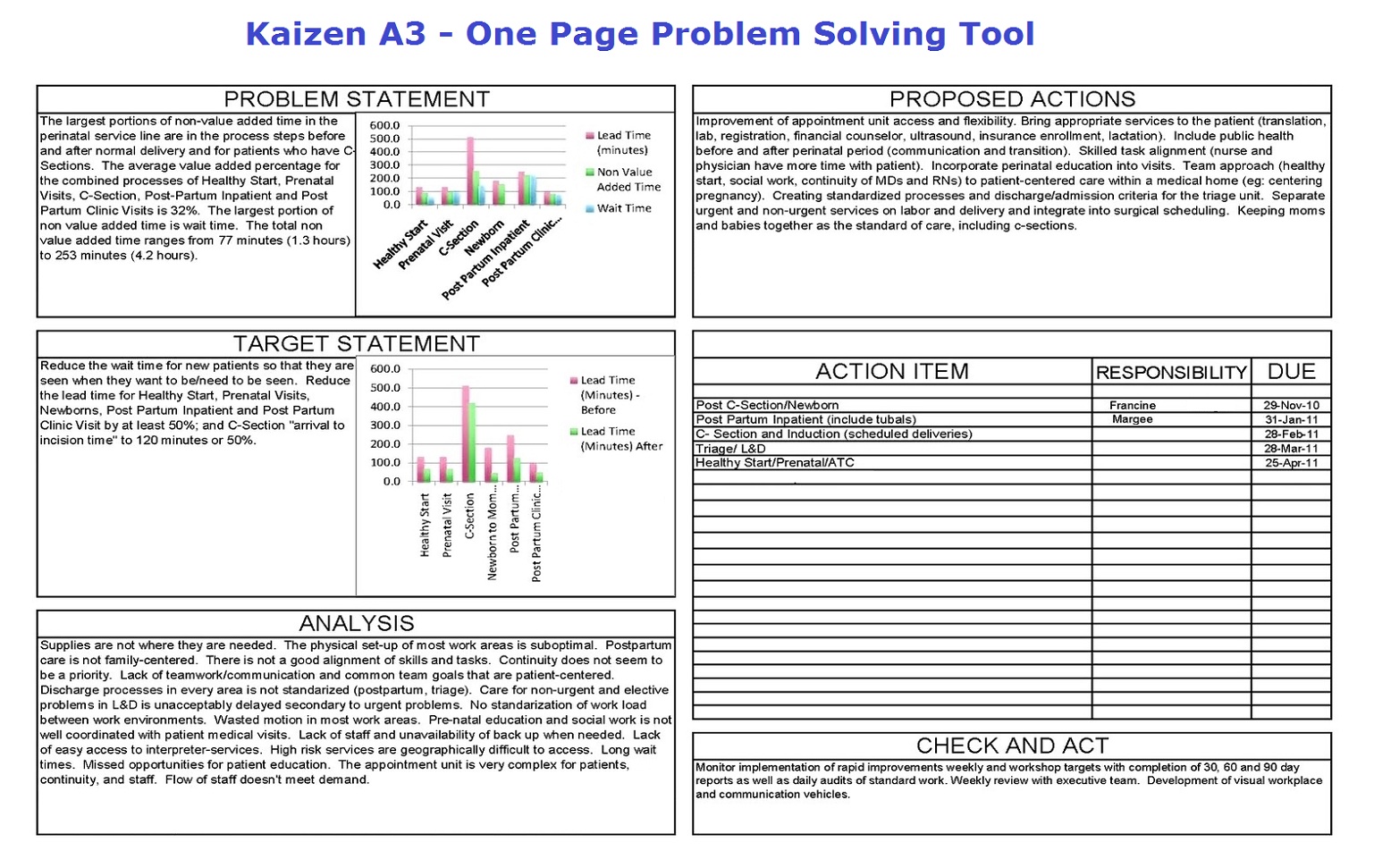

The first step in improving processes is to choose a process to improve. This process should be one that is critical to the business and has the potential to provide significant benefits when improved. Once a process has been selected, the next step is to map out the current process. This involves identifying all the steps involved in the process and documenting them.

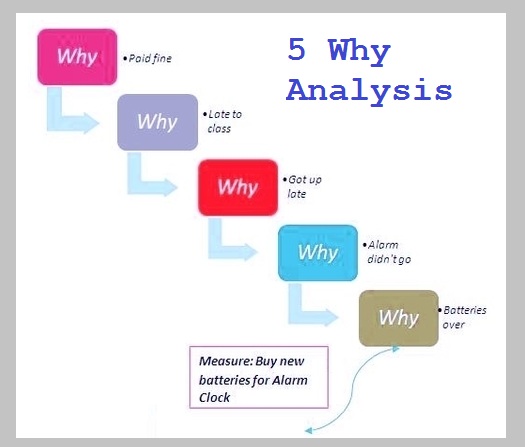

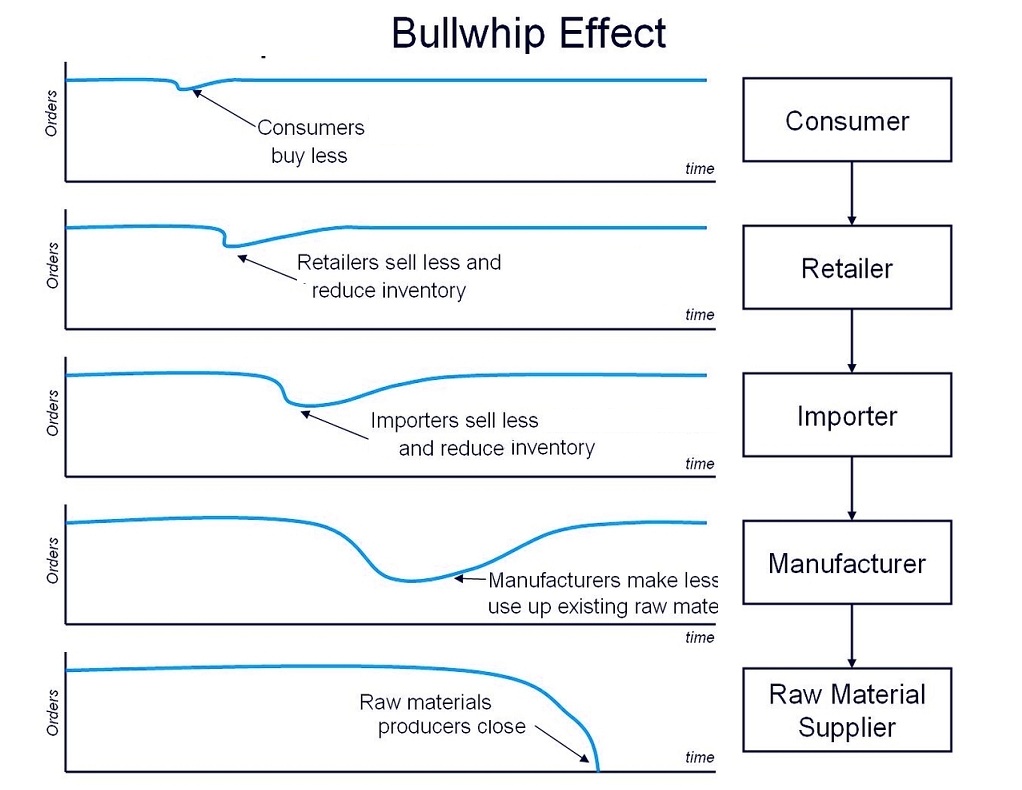

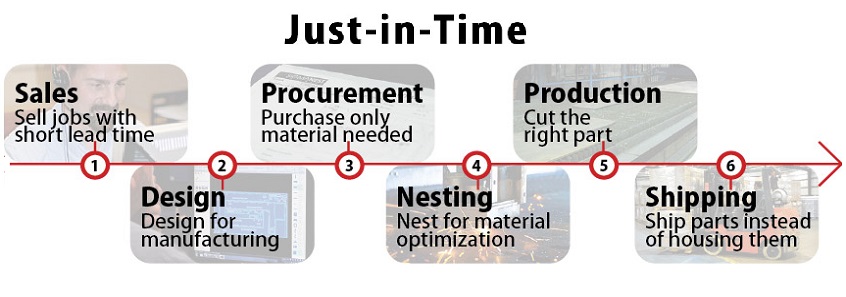

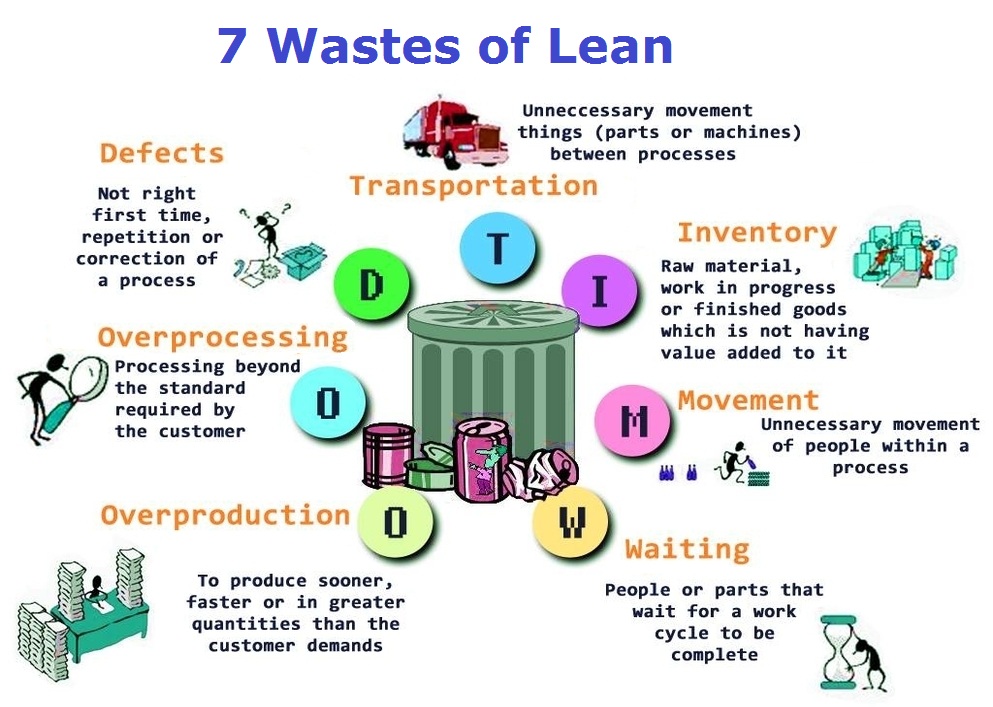

The third step is to identify bottlenecks and areas for improvement. This involves analyzing the current process to identify areas where there is waste, duplication, or inefficiency. Once these areas have been identified, the next step is to map out the potential new process. This involves designing a new process that eliminates the bottlenecks and inefficiencies identified in the current process.

The fifth step is to test the new process and revise it as necessary. This involves implementing the new process on a small scale and monitoring its performance. If the new process is successful, it can be rolled out on a larger scale. If the new process is not successful, it may need to be revised and tested again.

Finally, the new process should be implemented. This involves training employees on the new process and ensuring that they have the necessary resources to implement it effectively. The new process should also be monitored to ensure that it is achieving the desired results.

In conclusion, process improvement is a critical component of any business. It helps businesses optimize their processes to improve quality, performance, speed, or anything else that can make a process more efficient and provide a better experience for users and employees. There are different methodologies that businesses can use to improve their processes, including Six Sigma, Lean, and BPM. The process of improving processes involves choosing a process to improve, mapping out the current process, identifying bottlenecks and areas for improvement, mapping out the potential new process, testing the new process and revising it as necessary, and finally implementing the new process.