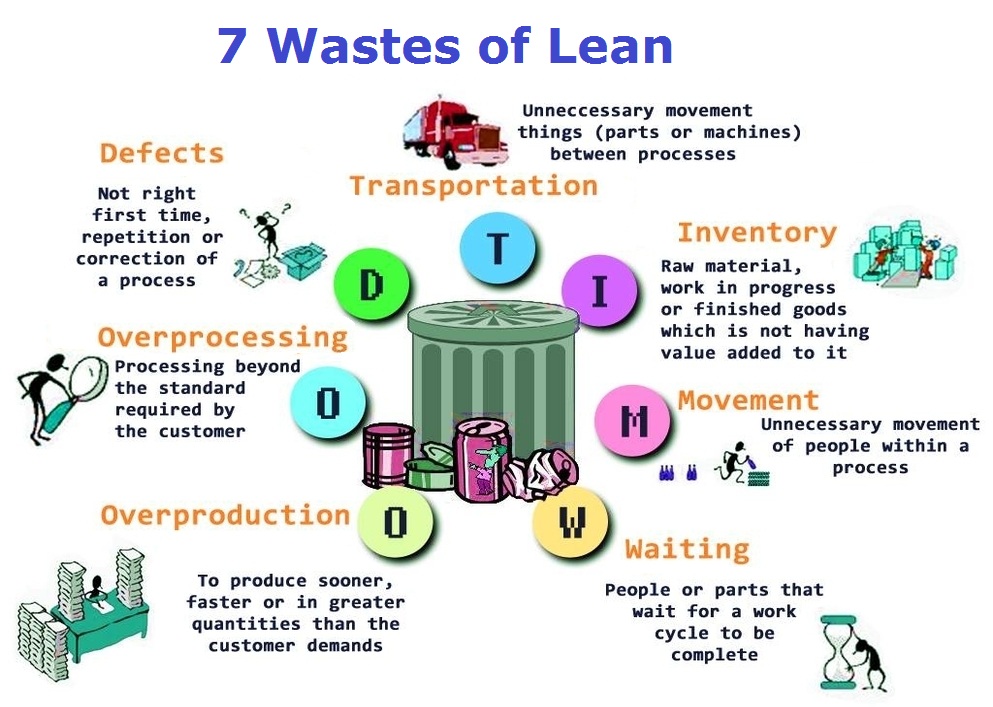

7 Wastes – Seven Wastes – 7 Wastes of Lean – This lean six sigma methodology (also known as 8 wastes) helps identify waste and other types of issues in the workplace. The 7 wastes framework includes defects, transportation, inventory, overprocessing, movement, overproduction and waiting.

Defects are wasted products completed not right the first time around. Inventory and overproduction are excessive quantities of raw materials or finished products. Transportation and movement are unnecessary movement of things or people. Overprocessing is making the product beyond customer expectations and waiting is simply waiting for materials, preventing timely completion of products. 7 Wastes Analysis – 7 Wastes Framework