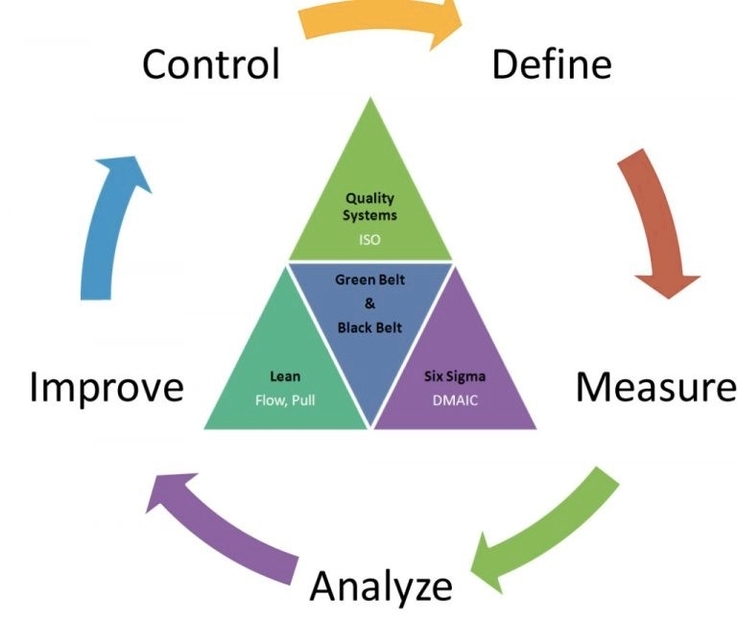

Lean Six Sigma is a process improvement approach that combines the principles of Lean and Six Sigma. Lean focuses on eliminating waste and non-value-adding activities, while Six Sigma focuses on reducing defects and variation in processes. Lean Six Sigma aims to improve performance, quality, and customer satisfaction by using a systematic and data-driven method.

The main steps of Lean Six Sigma are:

– Define: Identify the problem, the customer requirements, and the project goals.

– Measure: Collect data on the current process and its performance.

– Analyze: Identify the root causes of waste and defects, and the opportunities for improvement.

– Improve: Implement solutions to eliminate or reduce waste and defects, and test their effectiveness.

– Control: Monitor and sustain the improved process, and prevent it from reverting to the old state.

Lean Six Sigma uses various tools and techniques to support each step, such as value stream mapping, 5S, fishbone diagram, Pareto chart, hypothesis testing, design of experiments, control charts, and more.

Lean Six Sigma also has different levels of certification, based on the belt colors. The highest level is the black belt, followed by the green and yellow belts. Each level requires a certain amount of training, experience, and knowledge of the Lean Six Sigma tools and methods.

Lean Six Sigma is widely used in various industries and sectors, such as manufacturing, healthcare, finance, and supply chain, to achieve operational excellence and customer satisfaction.